The best option to simulate a mechanism with CATIA V5 is of course by using the dedicated one named DMU Kinematics Workbench. But as CATIA is a very interactive and versatile CAD software some simulation can be also done in other workbenches. For example sketch animation is sometimes a very useful feature and this can... Continue Reading →

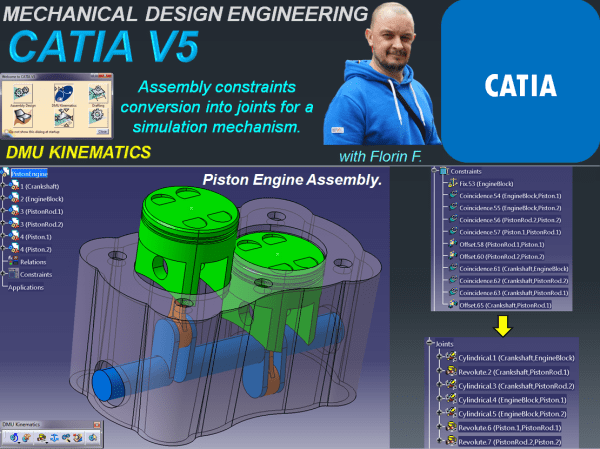

CATIA V5 _DMU KINEMATICS_Assembly constraints conversion into joints for a simulation mechanism.

In most cases when you want to do a mechanism simulation with CATIA V5, you perform this, using the DMU KINEMATICS Workbench where you initially prepare your assembly mechanism by only arranging the parts in an approximate position without defining the constraints. This is because in DMU Kinematics before to simulate your mechanism you must... Continue Reading →

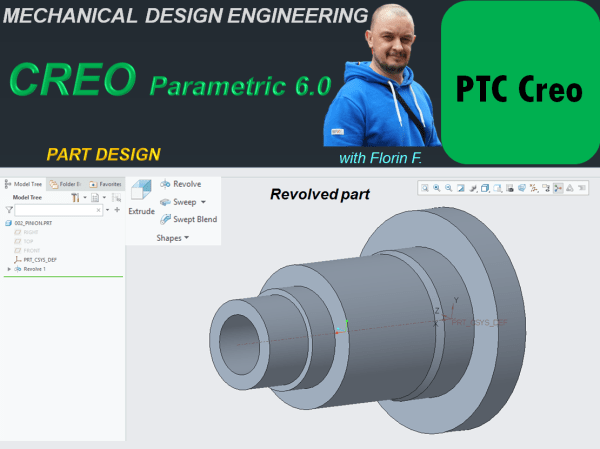

CREO PARAMETRIC 6.0 – PART DESIGN_Revolved part

A very frequent type of feature used in mechanical design development is the Revolved feature. There are many common working approaches with the Extruded part but as we are dealing with a different shape in this post I will show you how specifiaclly a Revolved part is created with CREO Parametric 6.0. STEP 1: As... Continue Reading →

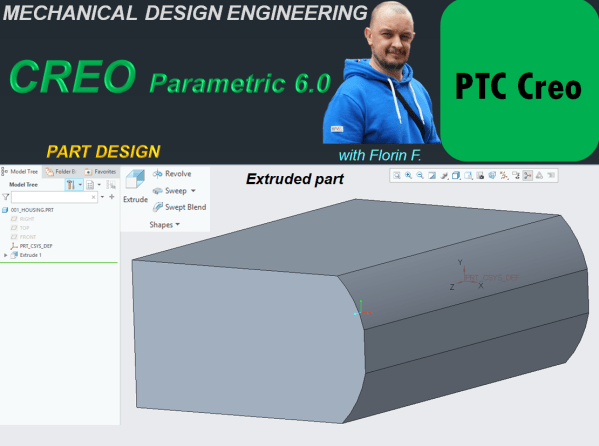

CREO PARAMETRIC 6.0 – PART DESIGN_Extruded part

In the past a job as mechanical designer was a little bit of more hard work to do becasue products were first drawn by hand using large sheets of paper and many hours to put all the technical and geometrical specification on it which then had to be used in production. Today things are completelly... Continue Reading →

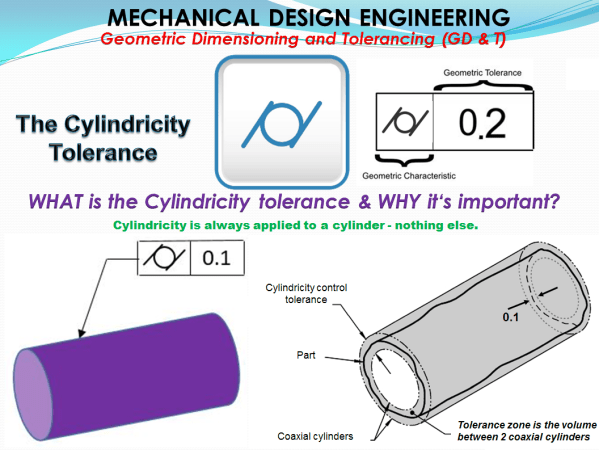

MECHANICAL DESIGN ENGINEERING – Geometrical Dimensioning and Tolerancing_What is the CYLINDRICITY tolerance?

2 simple geometrical elements are responsible to describe any geometrical shape. These are the Straight Line and the Circle. If you connect a line with at least one external non-collinear point you get a plane. If you extrapolate a circle towards an external point in perpendicular direction to the center point you get a cylinder.... Continue Reading →

MECHANICAL DESIGN ENGINEERING – Geometrical Dimensioning and Tolerancing_What is the CIRCULARITY tolerance?

In mechanical design of things, any object is defined by 2 geometrical forms: the straight line and the circle. A combination between the 2, results in complex surfaces. Therefore we can clearly say that next to the straight line, the circle is the second basic geometrical form in the entire technique. Maintaining the circularity (roundness)... Continue Reading →

CATIA V5 _DMU KINEMATICS_Generate a tracking line in a 3D simulation_WindShield Wiper

For this exercise I am gonna show you how to generate a tracking line in a 3D simulation which can be very useful in many situations. Let´s say for example the windshield wiper: You simulate its motion but you also want to see exactly the area in which the wiper moves. For this is very... Continue Reading →

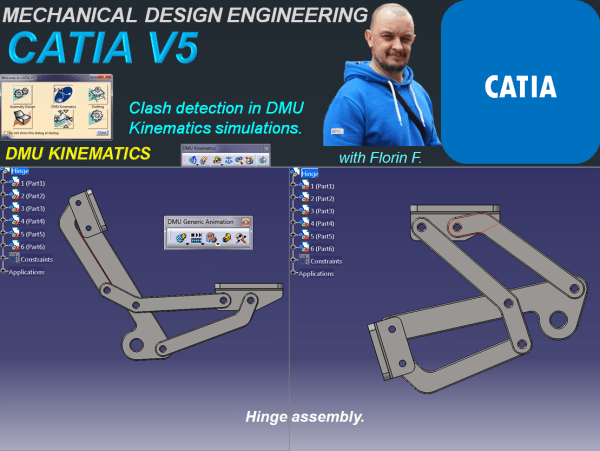

CATIA V5 _DMU KINEMATICS_Clash detection in DMU Kinematics simulations_Hinge assembly.

It is often the case that you want to make sure your mechanism works properly without clashes between its component parts. DMU Kinematics offers you the possibility to check your mechanism during simulation and easily detect any possible clash that might occur when you put your mechanism at work. Actually this is a very simple... Continue Reading →

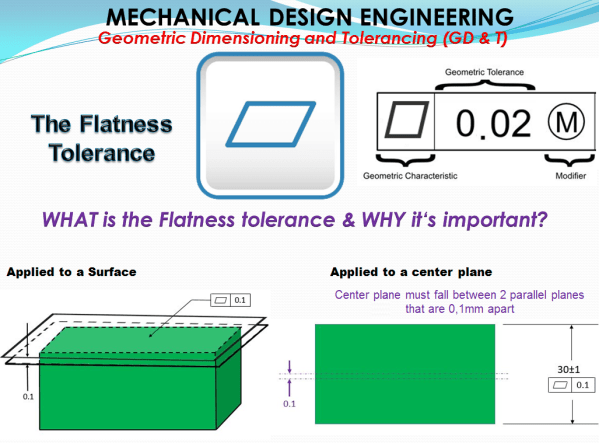

MECHANICAL DESIGN ENGINEERING – Geometrical Dimensioning and Tolerancing_What is the FLATNESS tolerance?

All the time when you want to make sure something is accurately closed/sealed the parts that are joined in your mechanical assembly product must have a specified restriction for how tight that closure must be. For this reason is essential that these parts are designed by default with such important specification which in Mechanical Design... Continue Reading →

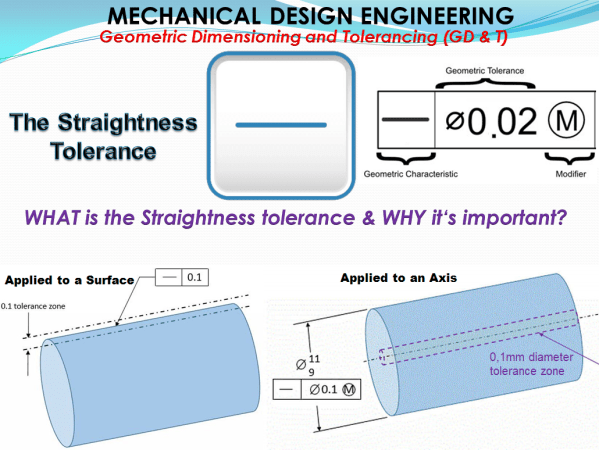

MECHANICAL DESIGN ENGINEERING – Geometrical Dimensioning and Tolerancing_What is the STRAIGHTNESS tolerance?

In every new product development process there are different stages to go through until the first official release is available for mass production. In early stages of product development you have the opportunity to test as many prototypes as possible, nothing must be strictly defined; however after few iterations, many tests and approval processes you... Continue Reading →