Energy is all around us. It’s responsible for making everything happen, whether you want to use any household appliance, take a walk through the park, drive your car across town, or do anything that involves movement or activity. Energy is the ability to do work and work in this context is when a force acts... Continue Reading →

DESIGN- DENK: Warum eine gute Idee nicht mehr genug ist?

Die Innovation wurde beschrieben als “eine gute Idee die gut ausgeführt wird“. Das ist ein guter Anfang. Leider, die erste Hälfte dieses Satzes wird zu stark betont. Ich habe unzählige Beispiele für gute Ideen gesehen, die aus dem einfachen Grund der schlechten Ausführung nie am Anklang gewonnen haben. Die meisten von ihnen erreichen nie den... Continue Reading →

COPPER – From the 1st metal used by humans to the essential element in technology development_PART II – How is Copper capable to harness the technology development in Digital Age?

Copper was the first metal used by man and still remains very much essential for technology development in the future. No other metal is able to beat Copper. It all started when Copper made the Bronze Age possible some 5000 years ago, which lasted for at least 2000 years after being replaced with Iron Age,... Continue Reading →

COPPER – From the 1st metal used by humans to the essential element in technology development_PART I – What is Copper and why is useful?

I love to talk about Copper. I must say that before to become materials science engineer I was very much in touch with electronics and initialy I wanted to become electronics engineer but it was Copper the metal that fascinated me since the beginning when I created my first PCBs for my electronic circuits. So... Continue Reading →

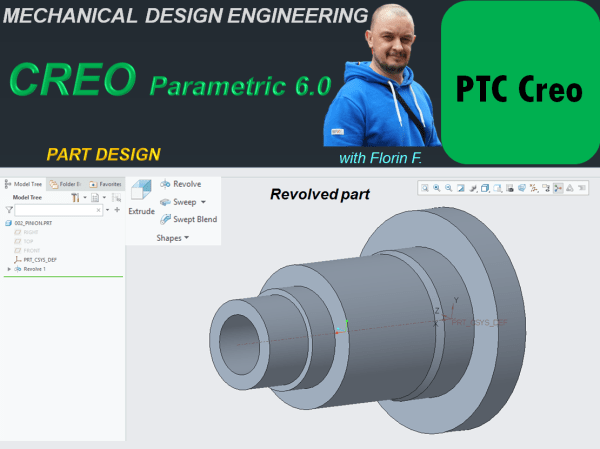

CREO PARAMETRIC 6.0 – PART DESIGN_Revolved part

A very frequent type of feature used in mechanical design development is the Revolved feature. There are many common working approaches with the Extruded part but as we are dealing with a different shape in this post I will show you how specifiaclly a Revolved part is created with CREO Parametric 6.0. STEP 1: As... Continue Reading →

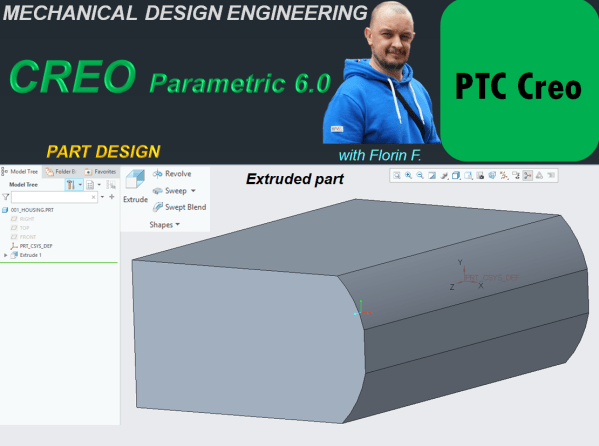

CREO PARAMETRIC 6.0 – PART DESIGN_Extruded part

In the past a job as mechanical designer was a little bit of more hard work to do becasue products were first drawn by hand using large sheets of paper and many hours to put all the technical and geometrical specification on it which then had to be used in production. Today things are completelly... Continue Reading →

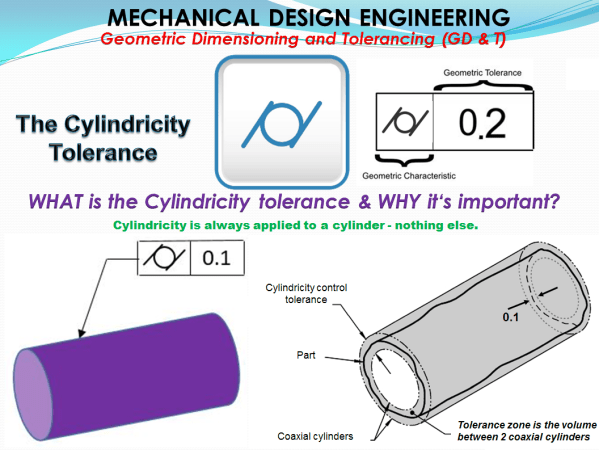

MECHANICAL DESIGN ENGINEERING – Geometrical Dimensioning and Tolerancing_What is the CYLINDRICITY tolerance?

2 simple geometrical elements are responsible to describe any geometrical shape. These are the Straight Line and the Circle. If you connect a line with at least one external non-collinear point you get a plane. If you extrapolate a circle towards an external point in perpendicular direction to the center point you get a cylinder.... Continue Reading →

MECHANICAL DESIGN ENGINEERING – Geometrical Dimensioning and Tolerancing_What is the CIRCULARITY tolerance?

In mechanical design of things, any object is defined by 2 geometrical forms: the straight line and the circle. A combination between the 2, results in complex surfaces. Therefore we can clearly say that next to the straight line, the circle is the second basic geometrical form in the entire technique. Maintaining the circularity (roundness)... Continue Reading →

CATIA V5 _DMU KINEMATICS_Generate a tracking line in a 3D simulation_WindShield Wiper

For this exercise I am gonna show you how to generate a tracking line in a 3D simulation which can be very useful in many situations. Let´s say for example the windshield wiper: You simulate its motion but you also want to see exactly the area in which the wiper moves. For this is very... Continue Reading →

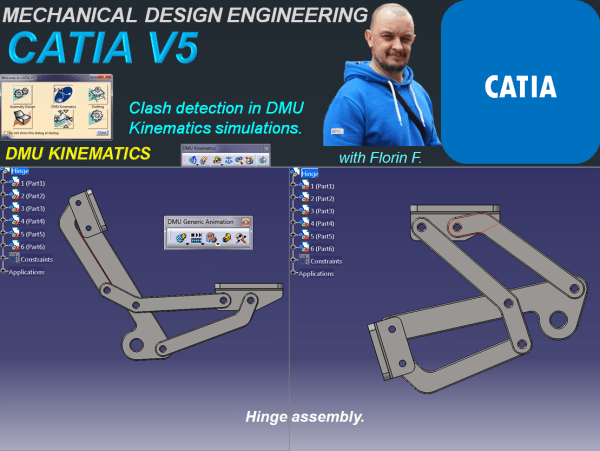

CATIA V5 _DMU KINEMATICS_Clash detection in DMU Kinematics simulations_Hinge assembly.

It is often the case that you want to make sure your mechanism works properly without clashes between its component parts. DMU Kinematics offers you the possibility to check your mechanism during simulation and easily detect any possible clash that might occur when you put your mechanism at work. Actually this is a very simple... Continue Reading →