Copper was the first metal used by man and still remains very much essential for technology development in the future. No other metal is able to beat Copper. It all started when Copper made the Bronze Age possible some 5000 years ago, which lasted for at least 2000 years after being replaced with Iron Age, but Copper was always there. Right at the start of Industrial Revolution when Iron was on the mainstream with the discovery of stainless steel, in the same time Copper did it again, and soon a new Age was possible because of it: The Electric Age. For the entire 20th century Copper had a massive impact on technology, making the Earth literally an Electric Planet.

In today´s 21st century Copper did it again making The Digital Age possible, and it very clear that Copper is capable to continuously revolutionize the technology in the future, I mean I don´t hesitate to say: Copper is the engine of technology forever. In this post I will present you some of the most recent impactful footprints made possible because of this supermetal called COPPER.

Copper’s Bright Past and Brighter Future

Here today, gone tomorrow; a truism in most cases, but not where copper is concerned. Copper is one of the most used and reused metals on earth. The copper used in your plumbing or cookware could have first been used hundreds, or even thousands of years ago. According to the U.S. Bureau of Mines and the U.S. Geological Survey, known copper resources are estimated at nearly 2.63 billion tons worldwide, only about 317 million tons of which have been mined to date. The recycling rate of copper is so high that nearly all of the copper mined throughout history – some estimates go as high as 80% – is still in circulation today. Every year in the U.S. only, nearly as much copper is recovered from recycled material as is mined. This is why the value of copper scrap remains so high, with premium-grade scrap maintaining at least 95 % of the value of newly mined copper.

Copper use has withstood the test of time. Pure copper was the first metal used by man, and copper artifacts, like a copper pendant that was discovered in what is now northern Iraq, date back to about 8700 B.C. The Egyptians took full advantage of mankind’s first metal. Copper saws, chisels, knives, hoes, dishes and trays made thousands of years ago by Egyptian coppersmiths have been uncovered from tombs in excellent condition, showing surprising durability and longevity.

Today, copper, and its alloys brass (Cu-Zn) and bronze (Cu-Sn), are used for faucets, locksets, door hardware, roofing, flashing, plumbing and electrical applications, as well as decorative products inside the home – the same unique characteristics that were admired centuries ago are still valued today. Concerns about copper resources being in jeopardy are unfounded and probably based on speculation. While there has been tremendous fluctuation in copper production over the last few years, there is no indication that resources are tapering. For those who were ever worried about copper production being in danger of coming to a halt, they can rest assured that it won’t happen. Aside from using recycled and mined copper in U.S. industries, there is also a tremendous amount of scrap metal that is exported. One of copper’s many attributes is its recyclability, it is also an extremely durable metal, and when you use copper for a project, you can be certain that it will last a lifetime. So, in addition to its inherent qualities of beauty, durability and low maintenance, copper is one of the most resource-efficient building materials available today, and it will continue to be readily available in the near and distant future.

Bridging Technology

Copper continues to be the standard for residential wiring needs. It really makes life super comfortable. We all can simply look at how the things are and we already have the answer to the following examples:

- On any given Sunday, why would anyone brave sub-zero degree temperatures at a football game when they could watch it in the comfort of home on a giant plasma flat screen with Dolby surround sound?

- Why drive to the mall to buy your favorite artist’s new album when, in seconds, it can be legally downloaded on your home computer?

- Why wake up and log on to your desktop when you could stay in bed and surf the Web wirelessly on your laptop?

Well… the reason to do all the suggestion mentioned in the above question is because of Copper. We can indeed do all that because Copper created the necessary tools for that, Therefore advances in technology are enabling us to create new routines and cast off the old ones. Each is anchored in convenience, can be performed with a mouse click, and completed while still in pajamas. Even as the power and prevalence of internet connections, home theaters and entertainment systems grow, one constant remains the bridge to newer technology: copper.

It’s not a secret that copper plays a major role when any kind of wiring is involved. The latest generation of copper communications wiring is Augmented Category 6 copper wiring, commonly referred to as “Cat-6a.” Once preferred for commercial office environments, Cat-6a is now being implemented more and more for residential use. This Cat-6a is designed to handle 10Gb/s (Gigabits per second) data rates. This makes it ideal for installing multiple applications through the network simultaneously. It allows large-file transfers and bundled cable implementations for channels up to 100 meters. And, it can support high-end security applications and the distribution of digital audio and video. To illustrate its speed, via a 10Gb/s connection rate, downloading a typical DVD of about 3GB would take around just 24 seconds.

A lot of wireless used in residential applications is typically between 1-10Mb/s, with new wireless being around 50Mb/s, while 10Gb/s is currently ideal for commercial applications, as applications for the home rapidly progress, it seems 10Gb/s is well suited for future residential technology. To hook up High Definition Media Interface (HDMI), you need at least 5Gb/s for 1080 quality both of which are quickly becoming the benchmarks for any new TV purchase.

To handle this technology, there are two choices: fiber optics and copper. While fiber optics is preferred for government data transfers and commercial networks because of its secure lines and ability to cover large distances, copper remains more cost-effective, is equally suited to commercial and residential use, and makes up the last 100 meters of commercial networks. Also, copper can carry lower levels of power, enough to power security cameras, card readers or other devices in commercial and residential buildings.

Copper is cheaper and much easier to install. Copper mainly reaches 100 meters, and the extra distance fiber can offer is lost in residential settings. This technology is still pretty new. But already, we’re reaching milestones in commercial and also residential, success. Everything now is being built with 10Gb/s. So, despite the recession, the future is looking green.

Computer Chips

We are constantly finding new and inventive uses for copper – especially in technology. This is due to the fact that copper is one of the best conductors of electricity, making it heralded by all computer chip manufacturers. For many years no one was able to produce a marketable copper chip, but in the last few years chip technology has reached groundbreaking new levels. It is now possible for chip makers to use copper wires, rather than traditional aluminum interconnects, to link transistors in chips. IBM and Motorola plan to replace aluminum (Al) with copper (Cu) in the computer chips they manufacture. This breakthrough technology enables conductor channel lengths and widths to be significantly reduced. The result is much faster operating speeds and greater circuit integration – up to 200 million transistors can be packed onto a single chip.

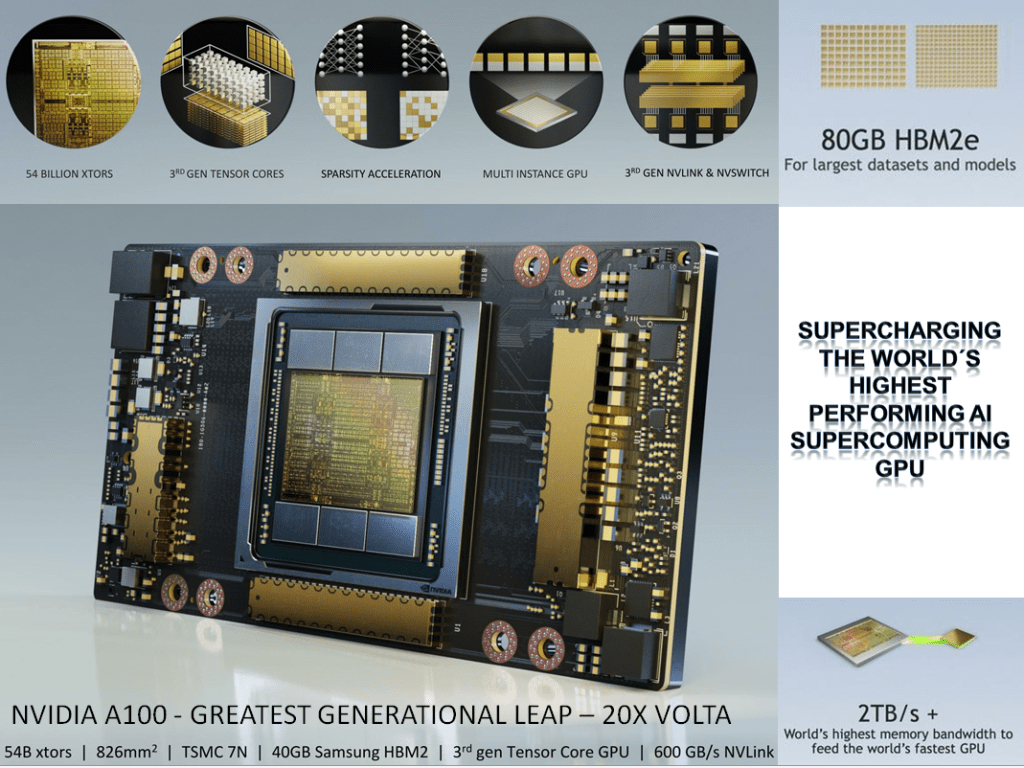

Likewise in 2020 Nvidia Unveiled Its Next-Generation 7nm Ampere A100 GPU for Data Centers, which is Absolutely Massive = 7nm FinFET process and 54 billion transistors. As the NVidia CEO himself Jensen Huang revealed this GPU has a million drill holes. 30,000 components, 1 kilometer of traces and all its heat pipes are made of Copper.

Ampere will inevitably make its way into some of the best graphics cards and find a place on our GPU hierachy, the Nvidia A100, is a GPU designed primarily for the upcoming wave of exascale supercomputers and AI research. It’s the descendant of Nvidia’s existing line of Tesla V100 GPUs, and like Volta V100 we don’t expect to see A100 silicon in any consumer GPUs. Well, maybe a Titan card—Titan A100?—but I don’t even want to think about what such a card would cost, because the A100 is a behemoth of a chip.

Let’s start with what we know at a high level. First, the Nvidia A100 will pack a whopping 54 billion transistors, with a die size of 826mm square. GV100 for reference had 21.1 billion transistors in an 815mm square package, so the A100 is over 2.5 times as many transistors, while only being 1.3% larger. Nvidia basically couldn’t make a larger GPU, as the maximum reticle size for current lithography is around 850mm2. The increase in transistor count comes courtesy of TSMC’s 7nm FinFET process, which AMD, Apple, and others have been using for a while now. It’s a welcome and necessary upgrade to the aging 12nm process behind Volta.

Along with the monster GPU itself are six stacks of high-bandwidth memory (HBM2e), which provide 40GB of total memory capacity (up to 80 gigabytes (GB)), A100 delivers a world’s first GPU memory bandwidth of over 2TB/sec, as well as higher dynamic random-access memory (DRAM) utilization efficiency at 95%. A100 delivers 1.7X higher memory bandwidth over the previous generation. The Nvidia A100 isn’t just a huge GPU, it’s the fastest GPU Nvidia has ever created, and then some. Let me reiterate that this GPU is not going into GeForce any time soon. All of this is great news for supercomputer and High-Performance Computing (HPC) use, but it leaves us with very little information about Nvidia’s next generation Ampere GPUs for consumer cards. I know that Nvidia crammed in 2.5 times as many transistors in roughly the same die space, which means it could certainly do the same for consumer GPUs. The use of copper conductors in chips is the last link in a now unbroken copper chain comprising the electric data path between user and computer. From external cables and connectors to bus ways to printed circuit boards, sockets and leadframes, it’s all copper.

Copper and Cars

Copper is very important for cars too. For example, there’s more than 25kg of copper in a typical U.S.-built automobile: about 20kg for electrical and about 5kg for nonelectrical components. Today’s luxury cars, on average, contain some 1500 copper wires totaling about 1,6km in length, thanks to continuing improvements in electronics and the addition of power accessories. In 1948, the average family car contained only about 55 wires amounting to an average total length of 45 meters. Just as electronics and power accessories have improved – with a little help from copper – other automobile applications have begun experimenting and using copper-based products over others as well.

CuproBraze is the name of a new manufacturing process for copper-and-brass automotive radiators. The process uses fluxless, lead-free brazing, anneal resistant alloys and laser welding among other innovations to produce new thin-walled radiators that perform better than thicker-walled aluminum products. CuproBraze radiators are typically 30% to 40% lighter than traditional copper and brass models, can be made smaller than their aluminum counterparts, and can provide up to 30% less air-side pressure drop. The CuproBraze process also shortens manufacturing time, is environmentally-friendly and reduces production costs.

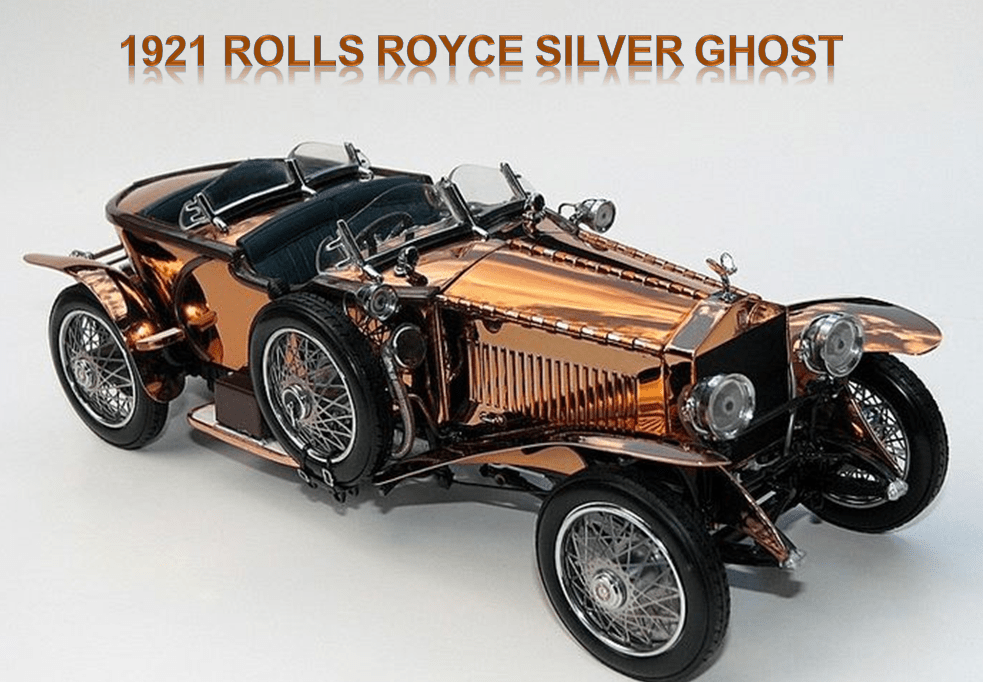

And by the way did you know… The body of the 1921 Rolls Royce Silver Ghost is completely copper. Nearly all of the car’s engine hardware is solid brass. And, of course, it has a copper and brass radiator.

Leave a comment